The HCM City Integrated Circuit Development Programme and investment in minimal fab, a small-scale, low-cost method of manufacturing semi-conductors are vital to making HCM City a smart city, experts have said.

The HCM City Integrated Circuit Development Programme and investment in minimal fab, a small-scale, low-cost method of manufacturing semi-conductors are vital to making HCM City a smart city, experts have said.

The programme, to run from 2013 to 2020, seeks to develop the integrated circuit industry in the city through training, research programmes and support to IC manufacturers to aid HCM City’s plan to become a smart city.

Under the programme the Saigon Industry Corporation is set to build a US$330 million silicon chip plant, with production capacity of 5,000 - 10,000 wafer per month.

The chip plant was approved by the Prime Minister on 2015 to be a part of the city’s hi-tech industry development strategy.

Because of its importance, the project is being considered to enjoy preferential credit policies. For instance, it may get loans with preferential interest rate from Viet Nam Development Bank, which is equivalent to 60 per cent of the project’s investment.

The project will likely be exempted from import tax for materials and components up to five years and get zero Value Added Tax for imported technologies not yet developed in Viet Nam to serve the plant’s activities.

Chu Tien Dung, general director of Saigon Industry Corporation, said his company was working on a feasibility study with partners, and would finish it by the end of August.

The programme has attracted many international experts.

Prof Dang Luong Mo, an expert in integrated circuit, said Viet Nam had seen a lot of improvement in IC design, but had difficulty with technology and funding.

Referring to the minimal fab model, Dr Wakabayashi of Japan’s Shinshu University said as a system that can produce semi-conductors for ICs on a smaller scale and requires much less investment and space compared to normal manufacturing, it is highly suitable for Viet Nam.

"Minimal fab requires only 1/1,000th of the investment a normal IC manufacturing facility does, allows manufacture of chips in a room measuring just a few square metres and provides a great learning opportunity for researchers," he said.

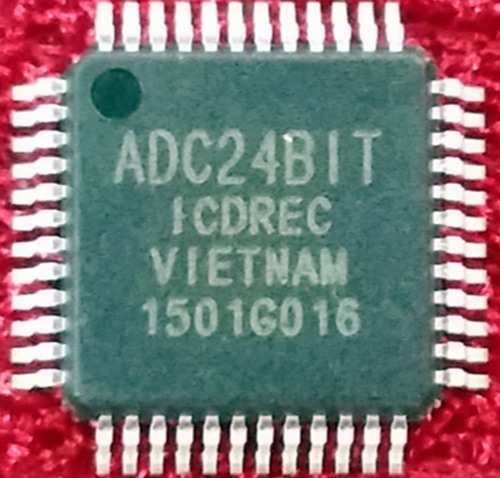

The city-based Integrated Circuit Design Research & Education Center announced it would switch from 180-nanometre technology to 65-nanometre technology for its chips to better suit minimal fab.

In 2015 Saigon Hi-tech Park Research Laboratories signed a memorandum of understanding for training and transfer of minimal fab technology with the Japanese Minimal Fab Development Association.

The transfer is expected to take place by the end of this year. — VNS