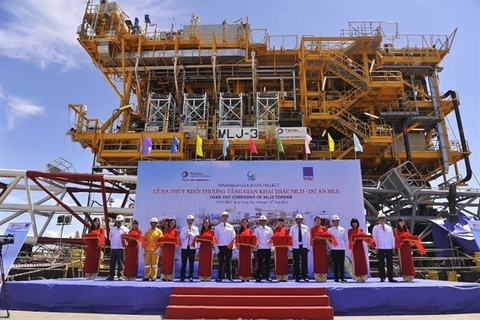

The load-out ceremony of the topside of Maharaja Lela Jamalulalam 3 of the Maharaja Lela South Project, which is implemented by PetroVietnam Technical Services Corporation Mechanical & Construction (PTSC M&C), in southern Vung Tau Province. — Photo courtesy of PTSC M&C

Viet Nam’s marine mechanical engineering has won many bidding packages worth tens of millions of dollars.

Among them, PetroVietnam Technical Services Corporation Mechanical & Construction (PTSC M&C) shines bright as one of the leading companies in engineering, procurement, construction and installation contractors.

For the past 10 years they have been providing a quality service not just in Viet Nam but the entire region in the country and the region.

PTSC M&C was formerly Marine Mechanical Service Enterprise. It was established with 67 employees to design and manufacture the Block 140 man (LQ-CPC99) oil rig for the Russia-Vietnam Joint Venture Vietsovpetro.

At the end of 2005, PTSC M&C was for the first time invited to take part in the international bidding process for Bunga Tulip A Project.

In order to win this package, PTSC M&C had to reduce the lowest bidding cost and minimise the manufacturing costs. Their bid was succcessful.

In July 2006, Bunga Tulip A project was completed. Although the economic value of the project was not high, PTSC M&C has successfully won the trust of international customers.

The name of PTSC M&C has become familiar in regional tenders. In mid-2007, PTSC M&C won the Black Lion of Cuu Long Joint Operating Company.

This started a golden age.

When the customer had a project requiring complicated techniques and high economic value they turned to PTSC M&C.

Blackbird Oil Field of Premier Oil, White Rhinoceros Oil Field of Hoang Long Joint Operating Company, and especially the East Sea 01 of Bien Dong Joint Operating Company were came calling, and PTSC M&C were happy to answer, and deliver a quality service.

The East Sea 01 project worth more than half billion dollars included the construction of the oil platform of Hai Thach Technology Centre and its jacket – the steel frame supporting the deck and topside of the platform.

Also the Moc Tinh 1 oil platform and its jacket, a leading bridge with about 70km of pipelines and 20km of underground cable with the total volume of over 60,000 tons.

PTSC M&C had to mobilise more than 3,000 engineers and skilled staff to work around-the-clock to meet the demands of the project.

The completion improved PTSC M&C’s market position, making it one of the most prestigious and high quality petroleum engineering service providers in Viet Nam and in the region.

In mid-2013, PTSC M&C officially signed a contract with AFCONS Infrastructure Limited to get the package of procurement of main materials and construction and pre-trial test of the Heera Technology Rig, which was part of the Heera Redevelopment Project in Mumbai, India.

It has become a milestone for Viet Nam's marine mechanical engineering industry as the project helped exporting rig in the world.

A series of projects for foreign investors followed, such as MLS Project of Total E&P Borneo BV in Brunei, Ghana OCTP Offshore of FPSO in Ghana, Greater Enfield Project for Technip and Daman Project for ONGC in India.

These projects helped secure the jobs for employees of PTSC M&C in the period of 2014-2017 – an extremely difficult time for domestic and foreign service companies.

In 2018, PTSC M&C continued to affirm its leading capability in the field of marine engineering in Viet Nam when it won an engineering, procurement, construction and installation contract worth US$330 million for the development of Gallaf (Al Shaheen) project invested by Qatar’s North Oil Company.

Under this contract, PTSC M&C designed, procured, manufactured, conducted pre-test, and completed offshore construction of the project.

The detailed design work was mostly implemented by PTSC M&C’s engineers.

PTSC leaders said the implementation of detailed design has helped control errors and ensure the progress of projects. The construction of a jacket shortened from 10-11 months to five months, and the construction of the topsides shortened from 16-18 months to 9-10 months.

It helped saving the cost as there was no need to mobilise dozens of project managers, experts and engineers to supervise and perform design and procurement work abroad. The unexpected cost arising during the implementation of the project was limited. This helped PTSC M&C to keep its competitive bidding prices.

PTSC M&C has gained a lot of faith of both domestic and foreign investors in the field of oil rig infrastructures because of its capacity and reputation, which has been built with a lot of effort of engineers and skilled workers of the company. — VNS