UPM Raflatac recently announced the launch of certified label material to fight ocean bound plastic pollution.

UPM Raflatac recently announced the launch of certified label material to fight ocean bound plastic pollution.

With the launch, the company has become the first company in the world to invest in Ocean Bound Plastics (OBP) waste as the raw material in their new ocean action labels.

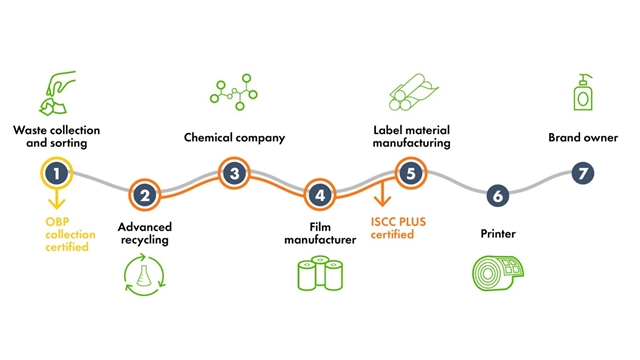

According to the company, the ocean action labels are made from ocean bound plastic using a mass balance approach. Ocean bound plastic is abandoned plastic waste recovered from areas up to 50km inland from waterways, defined as “at risk of ending up in the ocean” by OBPCert. The new innovative label material is made possible by close collaboration with multiple partners in the product’s value chain.

”The new innovative ocean action label material is the latest step in our beyond fossils journey. It does not only help prevent the plastic waste from ending up in the oceans but also offers brand owners the possibility to meet their recycled content targets for packaging. The ocean action label material is an easy-to-use drop-in solution created especially for food and cosmetics end-uses as it has exactly the same performance as the current fossil-based labels,” says Eliisa Laurikainen, business development manager from UPM Raflatac.

To make the ocean action label a commercially successful product, UPM Raflatac has collaborated closely with multiple partners in the value chain. The collaboration is necessary to make a circular economy a reality. At the first stage HHI, a Malaysian-based plastic recycling company, collects and sorts the ocean bound plastic waste with its partners. HHI has ocean bound plastics certification under the Zero Plastic Oceans program that ensures the responsible sourcing, proper collection and management of ocean bound plastic waste.

After collecting and sorting ocean bound plastic waste, HHI uses chemical recycling to convert the waste into pyrolysis oil. The pyrolysis oil is then used by SABIC to create high-quality PP plastic granulates.

The world desperately needs more sustainable and commercially viable ways to recycle post-consumer plastic. The United Nations has recognised the need to recycle more post-consumer plastic and has launched a new plastic pollution treaty in 2021. OBPCert has estimated that ocean bound plastic generates 80 per cent of plastic marine litter. Today, only around 10 per cent of plastic waste globally gets recycled, while the rest ends up at landfills, in incineration, and leakage to nature or oceans. One solution to this problem lies in creating markets for products made from ocean bound plastic. — VNS