Việt Nam’s capacity of processing and manufacturing industry remains limited and heavily relies on foreign supply chains for imported components and accessories thus leading to difficulties for local businesses, particularly in the context of COVID-19 pandemic.

Viet Nam’s capacity for the processing and manufacturing industry remains limited and heavily relies on foreign supply chains for imported components and accessories, leading to difficulties for local businesses, particularly amid the COVID-19 pandemic.

Trinh Thi Thanh Thuy, Deputy Director of the Institute of Industry and Trade Policy and Strategy under the Ministry of Industry and Trade, said last year countries with leading manufacturing and processing industries faced many difficulties, while Viet Nam was a bright spot with positive economic growth.

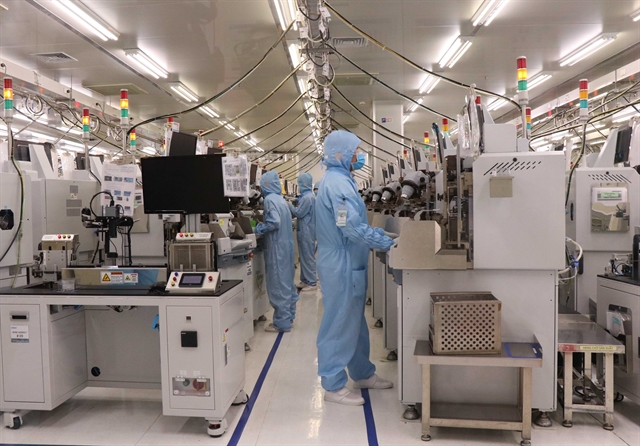

“The country’s positive growth is based on key manufacturing sectors, particularly those with high technology content and value such as electronics, electronic components, computers, and components for the automobile industry. Furthermore, agricultural processing and garment sectors have also obtained remarkable results,” Thuy said.

Pham Tuan Anh, Deputy Director of the Industry Department under the Ministry of Industry and Trade, said in 2016-19 domestic industries made a contribution of 30 per cent of the country’s gross domestic product (GDP), the largest contribution to State coffers.

Notably, the proportion of processing and manufacturing industries had increased rapidly without relying much on the mining industry.

In recent years, many industries have seen rapid development, such as electronics, textiles, and footwear with high export value.

Tuan Anh said the processing and manufacturing industry contributed the highest to GDP in terms of added value, creating a foundation for industrial development and modernisation of the country. The growth rate of the industry’s added value was much higher than the GDP growth in the last five years.

Policies needed

Despite some success, experts have said that the Vietnamese processing and manufacturing industry has failed to meet its potential.

Thuy said the most difficult problem was the lack of raw materials. Domestic manufacturers still rely greatly on foreign markets, particularly raw materials imported from China and South Korea. Thuy noted that business process outsourcing has been common in Viet Nam depending much on foreign direct investment (FDI) enterprises.

Tuan Anh said the problem was the development of strategies and policy planning were not suitable for economic development. Credit policies for businesses failed to meet their needs.

He noted that FDI enterprises in Viet Nam had been offered much preferential treatment from foreign credit institutions and parent companies with low interest rates. Meanwhile, loan interest rates offered by local banks were high, putting local firms at a disadvantage.

In addition, Viet Nam faces a lack of large-scale conglomerates to push the country’s economic development.

Tuan Anh added that the industrial sector needed a large amount of capital and a long period for investment capital retrieval. Therefore, it was urgent to call on domestic businesses to participate in the industrial sector.

To promote processing and manufacturing businesses to participate in the global supply chain, the department had worked with corporations such as Samsung and Toyota to create opportunities for local companies to work with foreign companies, said Tuan Anh. — VNS